The foundation of a house is the basic structure, responsible for the function of bearing the pressure and load of the entire project. Therefore, foundation construction requires time and highly precise technical elements and quality assurance. That's why supervising foundation construction work is one of the very important items in the construction process.

SUPERVISE EXCAVATION OF FOUNDATION HOLE

- Supervision consultant checks the reasonableness of the foundation pit excavation method established by the construction contractor. Check the excavator's features, excavated soil collection location, and excavated soil transportation vehicles.

- The construction supervision engineer rechecks the foundation excavation location, soil excavation diagram and sequence.

- When excavating the foundation, the bottom layer of soil must be reduced by at least 30cm to manually dig and repair the foundation to create a flat bottom surface and avoid breaking the structure of the foundation soil layer.

- The Construction Supervision Engineer checks the pit drainage method and cleans the foundation pit.

- Check and monitor the surrounding groundwater level during the foundation excavation process. If there is a phenomenon of groundwater withdrawal affecting neighboring structures, digging must be stopped and measures must be taken to promptly check and handle it.

- Check the elevation of soil layers excavated by machine and dig and repair foundation holes by hand. Check the size of the foundation pits, the bottom elevation of the excavation pit, and accept the excavation work according to the design drawings and soil construction standards TCVN 4447:1987.

- Supervise safety work during excavation of foundation pits.

SUPERVISE THE WORK OF BREAKING REINFORCED CONCRETE PILE HEADS AND POURING FOUNDATION LINING CONCRETE

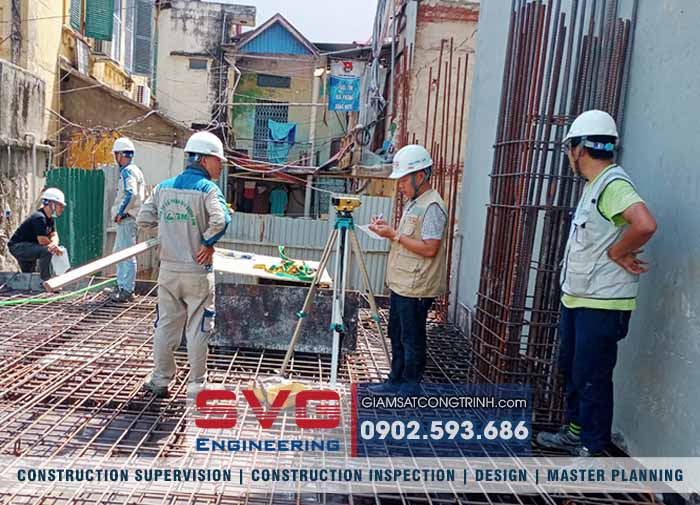

- Use design drawings and surveying machines to check and determine the location, size, elevation of the concrete foundation layer and the elevation of the pile head concrete dam marked on the construction Contractor's field site.

- Check pile head crushing equipment, quality of pile head concrete, and pile location ground.

- Check the concrete dam height at the pile head.

- Check the concrete mix design and foundation lining materials.

- Check the size, thickness and level of the concrete foundation lining layer.

- Check the quality and flatness of the concrete foundation lining layer.

- Check the maintenance of concrete foundation lining.

SUPERVISE FOUNDATION REINFORCED CONCRETE WORK

1. Supervision consultant (TVGS) supervises the preparation work:

- Commercial concrete supply contract, capacity and reputation of the mixing plant, ability to provide concrete to ensure progress and quality.

- Formwork, spears and supports are fully prepared for joining.

- Reinforcement is prepared of all types for the foundation.

- Prepare machinery and equipment for foundation reinforced concrete work.

- Prepare full acceptance procedures for materials used for the foundation.

2. Supervision of foundation reinforced concrete work:

Supervision of reinforcement, formwork and foundation concrete work complies with the basic construction supervision procedures described above. There are only a few points to note:

- Because the foundation construction site is large and the long foundation lines require high precision, it is required that the construction contractor must use a surveying machine to locate the shaft centers and the elevation for placing the reinforcement and foundation beams.

- There are many types of foundation reinforcement and the volume of steel is large, so the processing and erection of foundation reinforcement requires the contractor to have scientific organization and calculations and apply mechanization in construction labour.

- Strengthen checking of anchor length, reinforcement connection, steel bar position must be placed in the correct load-bearing area, and the thickness of the protective concrete layer must ensure according to the design.

- The steel bars linked together must form a sturdy frame, ensuring no movement when pouring and compacting concrete.

- Foundation formwork is large pieces, especially elevator tower formwork, so the Supervision Consultant (TVGS) needs to closely supervise the connection of formwork panels together. At the corners, the stations and beams must be connected with corner formwork.

- Check the stability of the formwork bracing and support system. The legs and support ends must be placed on a solid point and have an adjustable jack, and the tie bars must be welded together.

- When accepting formwork and steel reinforcement, attention should be paid to checking the cleanliness of the bottom of the foundation pit. Pump water to clean the reinforcement, remove mud and water from the bottom of the foundation.

- Foundation concrete is large block concrete, so when pouring, it is necessary to check measures to reduce heat for the concrete. Pour concrete into layers, divided into 3 pouring times according to the height of the platform and foundation beams to reduce pressure on the formwork and give the concrete time to heat up.

- Foundation concrete is poured by pump, so the pressure is very high. During the pouring process, the contractor is required to always pay attention to the displacement of reinforcement and formwork to take timely measures.

- During the process of pouring concrete, always pay attention to the positions where the steel is waiting and the holes (if any).

- Supervise and check foundation pit drainage throughout the concrete pouring process.

- Supervise and check the maintenance of normal concrete, the minimum curing time is 7 days.

3. Supervision of foundation pit soil filling work:

After accepting the foundation concrete, check the work using a leveling machine to determine the height of filling the foot of the foundation and covering with clay.

- The supervision consultant (TVGS) checks the order of filling the soil layers, filling in order each layer with a thickness of ≤ 50cm and then using a rammer to compact.

- During the process of filling the soil, it is necessary to ensure that the humidity is within a controlled range: If the soil is dry, add water, if the soil is too wet, take measures to reduce the moisture so that the soil is compacted.

- After compacting each layer of soil to ensure compactness according to design requirements, proceed to filling the next layer of soil.

- Lớp đất sét chống thấm phải lựa chọn đất đảm bảo tiêu chuẩn, đất sét phải được băm nhỏ, rải đều và đầm chặt.

- Kiểm tra độ chặt và mặt phẳng lớp đất lấp.

PRESTIGIOUS CONSTRUCTION SUPERVISION SERVICE OF SVG ENGINEERING

Sao Viet Construction Design Consulting and Inspection Joint Stock Company (SVG Engineering) is a capable, dedicated and reputable company in Construction Supervision Consulting (TVGS) and legal support for Investors / Business owner to the best of his ability. We have experience in Construction Supervision for many diverse scale projects with a reputable brand of nearly 20 years. SVG Engineering is committed to providing quality, dedicated supervision consulting services... at reasonable costs to help customers/Investors/Business owners feel secure and satisfied.

SAO VIET CONSTRUCTION DESIGN CONSULTING AND INSPECTION JOINT STOCK COMPANY

EXPENSE OF CONSTRUCTION SUPERVISION IN VIETNAM

Please immediately contact Hotline: 0902.593.686 (Mr. Thang) & Email: svg.engineer@gmail.com for support and advice on issues related to Construction supervision in Viet Nam ... Best regards!

VietNam construction consulting - Mr. Thang 0902.593.686

CONTACT US:

SAO VIET CONSTRUCTION DESIGN CONSULTING AND INSPECTION JOINT STOCK COMPANY

🏢 Hai Phong Office :

SVG Building, Bui Vien Street, Le Chan District

☎ Tel: (0225) 3.747.819

📞 Hotline: 0902.593.686

📧 Email: svg.engineer@gmail.com & svg.group2005@gmail.com

🌎 VietNam Website: giamsatcongtrinh.com

🌎 English Website: en.giamsatcongtrinh.com

🌎 China Website: cn.giamsatcongtrinh.com

Youtube Channel: https://www.youtube.com/@svgengineering

Youtube Channel: https://www.youtube.com/@svgengineering

🏢 Representative offices:

1, Ha Noi: No. 9, Alley 81 Hoang Cau Street, Dong Da District

2, Ho Chi Minh: 2/1C Cao Thang Street, 05 Ward, 3 Distric