In the field of construction, concrete pouring is very important, concrete & reinforced steel are the main materials and create a strong and sustainable skeleton for the project. The quality of concrete determines the quality of construction work. During the construction process, if there are violations related to the process of pouring concrete columns, beams, and floors that do not meet technical requirements and standards, the quality of the concrete will decrease, causing damage, loss of safety, and adverse effects to the construction site.

SUPERVISION OF CONCRETE POURING OF BEAMS, FLOORS, AND COLUMNS IN VIETNAM

1 - SUPERVISION OF CONCRETE MIXTURE DESIGN

Need to comply with regulations on commercial concrete of Hai Phong City People's Committee.

- Must design the concrete mix composition (calculate and cast samples) according to the design grade.

- The slump and hardness of the concrete mixture depends on the structure of the project, steel content, transportation method, and weather. The slump (mm) and hardness (S) of the concrete mixture at the pouring location are as follows:

+ Foundation lining: Slump when machine compacted is 0 ÷ 10mm, hardness index is 50 ÷ 40mm.

+ Concrete block structure with little or no reinforcement, slump when machine compacted is (0 ÷ 20)mm, when compacted by hand is (20 ÷ 40)mm; Hardness index is (35 ÷ 25)mm.

+ Large block structure with average cross-section: Slump when machine compacted is (20 ÷ 40)mm; when compacted by hand, it is (40 ÷ 60)mm; Hardness index is (25 ÷ 15)mm.

- Reinforced concrete structures such as thin walls, columns, beams, small cross-section slabs, structures poured with mobile formwork: machine compaction slump is (50 ÷ 80)mm, when hand compacted is (80 ÷ 120)mm; Hardness index is (12 ÷ 10)mm.

- Concrete composition is adjusted on site according to the principle of not changing the N/XM ratio of the designed concrete composition. When the aggregate has high moisture content, it is necessary to reduce the amount of mixing water and maintain the required slump. When it is necessary to increase the slump of concrete, the amount of water and cement can be increased to maintain the N/MX ratio.

- Transporting concrete mixture:

+ When transporting commercial concrete, using appropriate equipment must ensure that the concrete does not stratify or lose cement water. Equipment used and manpower arranged in accordance with the volume and speed of pouring and compacting concrete.

+ The time allowed to store the mixture during transportation needs to be determined by experiment. When there is no experimental data, you can refer to the following data:

+ The mixture retention time on the transport vehicle when the temperature is >30°C is 30 minutes.

+ The mixture retention time on the transport vehicle when the temperature is from 20 ÷ 30°C is 45 minutes.

+ The mixture retention time on the transport vehicle when the temperature is from 10 ÷ 20°C is 60 minutes.

+ The mixture retention time on the transport vehicle when the temperature is from 5 ÷ 10C is 90 minutes.

2- SUPERVISION OF CONCRETE FILLING AND COMPACTING

Pouring concrete must ensure not to distort the position of reinforcement, formwork, and the thickness of the concrete layer protecting the reinforcement. Do not use rammers to move concrete horizontally in formwork. Concrete must be poured continuously until a certain structure is completed as prescribed in technical regulations. Free fall height of concrete ≤ 1.5 m to avoid stratification. When pouring concrete with a free fall height of > 1.5 m, you must use an elephant trunk or a pouring bag.

During the process of pouring concrete, you need to pay close attention to:

Supervise the construction of formwork, scaffolding and reinforcement. The thickness of the poured concrete layer is consistent with the data calculating the hardness of the formwork to withstand horizontal pressure caused by the concrete mixture. At any location where the structure of reinforcement and formwork cannot be compacted by machine, the new Use a hand dress. When it rains, there must be a cover to prevent rain from falling on the concrete. The thickness of the poured concrete layer must also be determined based on compaction ability, structural properties, and weather but must not exceed the following values:

- Compaction: The allowable height for each concrete layer is 1.25 of the working length of the compactor (about 20 ÷ 30 cm).

- Surface compaction: The allowable thickness of each concrete layer is 20cm for structures with single reinforcement; 12 cm for structures with double reinforcement.

- Requirements when compacting concrete: After compaction, the concrete is compacted tightly and free of porosity. A sign of thorough compaction is that the cement mortar floats to the surface and air bubbles are no longer there.

- The moving step of the compactor must not exceed 1.5 times the effective radius of the compactor.

3- CONCRETE MAINTENANCE SUPERVISION

Maintenance time is according to the following values:

- Dry season (February ÷ July): Time is 4 days until the concrete reaches its critical curing strength (55 ÷ 60% of 28-day strength).

- Rainy season (August ÷ January): time is 2 days until concrete reaches critical curing strength (35 ÷ 40% of 28-day strength).

4- CONCRETE INSPECTION SUPERVISOR

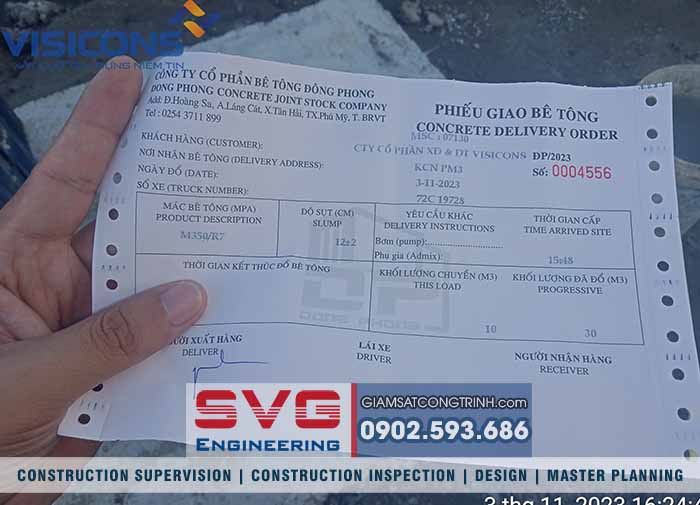

Concrete quality inspection is the synthesis of all work from formwork, scaffolding, reinforcement, materials for concrete production, concrete mixture manufacturing, slump when pouring concrete, tolerances. building structures.

Concrete samples must be taken at the scene at the same time and in the same place. The sample size is 15cm x15cm x 15cm, the number of sample groups taken is as follows:

+ For each batch of column foundation concrete, take a batch of samples for each batch or 50m3 of concrete. In case the batch of concrete for the column foundation has a volume of less than 50m3, still take a batch of samples.

+ Frame and column structures, beams, slabs, floors... take one sample for every 20m3 of concrete. In case the concrete pour of frame and column, beam structures... has less volume, still take 1 sample. sample group.

+ After 1 round of concrete pouring, the floor needs to take a group of samples to check waterproofing. The strength of construction concrete after testing at the age of 28 days by pressing samples at the laboratory is considered satisfactory when the average value of each group of samples is not less than the design mark and there is not a single sample in the groups. Samples have an intensity below 90% of the design mark.

5- ACCEPTANCE OF CONCRETE WORK

Acceptance work conducted at the site requires all of the following documents:

- Quality of formwork and reinforcement work (acceptance record before pouring concrete)

- Concrete quality (concrete sample compression test results).

- Size, shape, location, preset details... compared to design.

- As-built drawings have all dimensions changed during construction compared to the design.

- Documents allowing changes to details and parts in the design.

- Test results of concrete strength and test results of other materials.

- Minutes of intermediate acceptance of departments.

- Project construction diary.

- Internal acceptance minutes and acceptance request form of the Construction Contractor.

EXPENSE OF CONSTRUCTION SUPERVISION IN VIETNAM

Please immediately contact Hotline: 0902.593.686 (Mr. Thang) & Email: svg.engineer@gmail.com for support and advice on issues related to Construction supervision in Viet Nam ... Best regards!

VietNam construction consulting - Mr. Thang 0902.593.686

CONTACT US:

SAO VIET CONSTRUCTION DESIGN CONSULTING AND INSPECTION JOINT STOCK COMPANY

🏢 Hai Phong Office :

SVG Building, Bui Vien Street, Le Chan District

☎ Tel: (0225) 3.747.819

📞 Hotline: 0902.593.686

📧 Email: svg.engineer@gmail.com & svg.group2005@gmail.com

🌎 VietNam Website: giamsatcongtrinh.com

🌎 English Website: en.giamsatcongtrinh.com

🌎 China Website: cn.giamsatcongtrinh.com

Youtube Channel: https://www.youtube.com/@svgengineering

Youtube Channel: https://www.youtube.com/@svgengineering

🏢 Representative offices:

1, Ha Noi: No. 9, Alley 81 Hoang Cau Street, Dong Da District

2, Ho Chi Minh: 2/1C Cao Thang Street, 05 Ward, 3 Distric