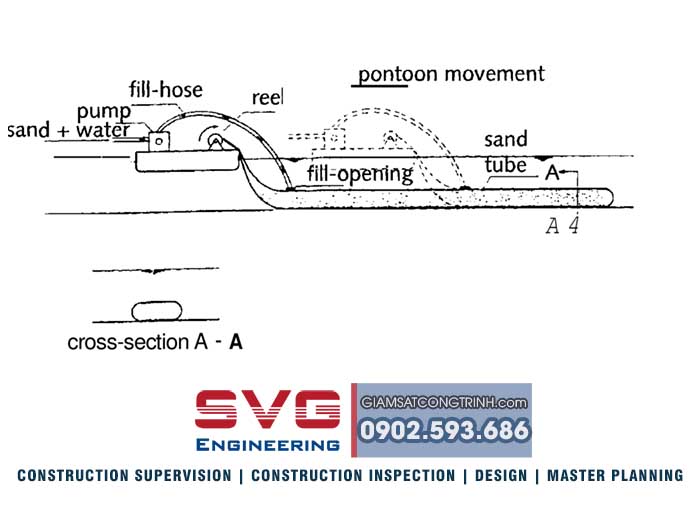

Geotube construction is a method of handling mud, sand, and other materials by pumping them into geotextile tubes, allowing water to drain through the filter fabric and form a solid, stable mass of material. The process includes laying and positioning the tubes, installing the pumping system, pumping the materials, densifying and stabilizing the structure, and completing the project. This method is commonly used in coastal works, sea dykes, land reclamation, and land reclamation, with the advantages of reasonable cost, quick construction, and environmental friendliness.

GEOTUBE PIPE CONSTRUCTION PROCESS

-

Tube preparation and positioning:

-

Unroll the geotubes to the designated location, checking carefully for any tears or damage.

-

Connect the tubes together if necessary and ensure they are properly secured in the design.

-

Pump system installation:

-

Pumping material into the pipe:

-

Pump material (such as sand, mud, or a mixture of materials) into the pipe.

-

Adjust the pump flow to ensure the material is evenly distributed, avoiding being concentrated on one side.

-

Solidifying and stabilizing the structure:

-

During pumping, water in the material will drain out through the geotextile layer, leaving the material inside the pipe to gradually dry and harden.

-

Additional polymers or other additives can be used to speed up the dehydration process and help the internal material solidify and stabilize faster.

-

Completion and maintenance:

-

Once completed, the pipe will form a soft dike or a solid structure, depending on its intended use.

-

Carry out necessary protection and maintenance measures according to project requirements and environmental conditions.

COMMON SIZES OF GEOTUBE TUBE

- Geotubes are designed in a variety of sizes, suitable for the scale and design requirements of the project. The seams of the geotextile tubes are sewn along the circumference of the tube. The tube is filled by hydraulic pumping through the filling port.

- Common tube sizes range from 1m to 3m in height and up to 100m in length. However, due to installation reasons, the common length of the geotube is usually 25-50m.

.jpg)

ADVANTAGES AND BENEFITS OF GEOTUBE PIPE CONSTRUCTION

- Application:

-

Building soft dikes, breakwaters on river banks and coastlines to prevent erosion.

-

Reclaiming land, improving land, creating small islands or building foundations.

-

Treating sludge, industrial and urban wastewater.

-

Making filter layers for irrigation works.

- Advantage:

-

Cost-effective: Material and construction costs are typically lower than traditional methods such as concrete or rubble.

-

Fast construction: Construction time is shortened due to the use of locally available materials and simple processes.

-

Environmentally friendly: Geotextiles are chemical resistant, corrosion resistant, non-polluting and help preserve coastal ecosystems.

-

Flexible and sustainable: Can be customized in size, shape and stacked to suit a variety of terrains and designs.

AN TYPICAL PROJECT OF SVG ENGINEERING

-

The Vung Xec - Do Son Ward - Hai Phong City project uses Geotube technology, with Sao Viet Construction Design Consulting and Inspection Joint Stock Company (SVG Engineering) as the construction supervision consultant unit. This is a key project using Geotube solutions to build a soft dike system. The application of Geotube in this project not only solves the complex technical problems of coastal terrain but also optimizes costs and is environmentally friendly, using on-site filling materials.

-

The project supervision and construction consulting process at Vung Xec also adheres to strict technical standards to ensure the quality of the project. The team of construction engineers and SVG Engineering experts closely supervised each stage, from the initial laying and positioning of Geotube pipes, testing of input materials, to controlling the pressure and flow of pumping materials to ensure uniformity and stability of the entire dike line.

IMAGES OF CONSULTING AND SUPERVISION OF GEOTUBE TUBE CONSTRUCTION PROJECTS OF SVG ENGINEERING

COST OF CONSTRUCTION SUPERVISION CONSULTING IN VIETNAM

Please immediately contact Hotline: 0902.593.686 (Mr. Thang) & Email: svg.engineer@gmail.com for support and advice on issues related to Construction Supervision Consulting in Viet Nam ... Best regards!

VietNam construction consulting - Mr. Thang 0902.593.686

CONTACT US:

SAO VIET CONSTRUCTION DESIGN CONSULTING AND INSPECTION JOINT STOCK COMPANY

🏢 Hai Phong Office :

Address : 7th floor SVG Building - Bui Vien Street - An Bien Ward - Hai Phong City

☎ Tel: (0225) 3.747.819

📞 Hotline: 0902.593.686

📧 Email: svg.engineer@gmail.com

🌎 VietNam Website: giamsatcongtrinh.com

🌎 English Website: en.giamsatcongtrinh.com

🌎 China Website: cn.giamsatcongtrinh.com

Youtube Channel: https://www.youtube.com/@svgengineering

Youtube Channel: https://www.youtube.com/@svgengineering

🏢 Representative offices:

- Ha Noi Branch Office : No. 9/ 81 Hoang Cau Street, Dong Da Ward, Hanoi Capital

- Ho Chi Minh Branch Office: 2/1C Cao Thang Street, Ban Co Ward, Ho Chi Minh City

- Hue Branch Office : M25 Lot , 21 Street, Dong Nam Thuy An, Thanh Thuy Ward, Hue City