The workshop is a complex operational system that directly impacts production efficiency, operating costs, and the enterprise's brand image. Many workshop design projects fail because they focus only on cost while neglecting optimal functionality, professional aesthetics, and legal risks. In this article, SVG Engineering presents a detailed, standardized 6-step factory design process, helping investors secure a perfect industrial facility from concept to construction drawings.

THE 6 STEPS PROCESS FOR WORKSHOP DESIGN ENSURING FUNCTIONALITY, LEGALITY AND AESTHETIC

STEP 1: SITE SURVEY, REQUIREMENT ANALYSIS, AND ESTABLISHING THE WORKSHOP DESIGN BRIEF

This foundational step determines the success of the entire project.

1. Core Factory Functionality Analysis:

-

Products and Technology: Clearly define the type of products to be manufactured, the technology, and the machinery line. This dictates the necessary clear height, column span, floor loading capacity, and utility systems of the workshop.

-

Logistics and Material Flow: Study the material flow (input, process, output, finished goods warehouse) to design an optimal factory layout (as discussed: U-shaped, Cellular, or Straight Line Flow).

2. Site Survey and Legal Requirements for the Workshop Construction Land:

-

Geological and Topographical Conditions: Conduct a geological survey to calculate the appropriate, cost-effective foundation solution. Conduct a topographical survey to calculate site leveling and drainage solutions.

-

Legal Constraints (Legal Compliance): Check the detailed land use master plan, construction density (or plot ratio), maximum building height, building setback limits, and specific regulations regarding Fire Prevention and Fighting (FPF/PCCC) and environment within the industrial park. Legal compliance must be the top priority.

3. Establishing the Workshop Design Brief:

STEP 2: PRELIMINARY DESIGN AND ESTABLISHING THE WORKSHOP ESTIMATE

This step translates the requirements into initial visuals and figures.

1. Proposing Architectural and Structural Solutions for the Workshop:

-

Preliminary Design: Present various options for floor plans, elevations, and overall site planning. Decide on the main structural system (Pre-Engineered Steel Structure, Reinforced Concrete, or a combination) for the workshop.

-

Aesthetic Solution: Determine the envelope materials (corrugated iron/steel sheet, sandwich panels, brick walls) and the primary color scheme. Modern aesthetics often prioritize simplicity, sustainable materials, and abundant natural light.

2. Establishing the Preliminary Cost Estimate (Conceptual Estimate):

-

Based on the built-up area and the preliminary structural/architectural solutions, establish the initial cost estimate. This gives the investor a general overview of the investment capital and allows for workshop design adjustments if necessary.

-

Note: This estimate must include civil construction costs, M&E (Mechanical and Electrical) costs, and other related expenses.

STEP 3: CONCEPTUAL DESIGN – DETAILING FUNCTIONALITY AND SYSTEMS

This is the most critical step for official approval by regulatory authorities and serves as the foundation for the detailed engineering design.

1. Completing the Legal Dossier (Conceptual Design / Basic Design):

-

Main Structural Solution: Preliminary calculation of column spans, bracing systems, roofing, and especially the Fire Prevention and Fighting (FPF/PCCC) system.

-

M&E System Integration:

-

Electrical: Location of the transformer station, main electrical cabinet, and production lighting system.

-

Water: Location of the underground water tank, FPF/PCCC water tank, and wastewater treatment system.

-

Ventilation/Air Conditioning: Calculation of airflow (volume) and placement of ventilation fans and industrial air conditioners.

-

Crucial Note: The FPF/PCCC dossier must be designed and submitted for appraisal/approval at this stage to ensure compliance with Vietnamese Technical Standards (QCVN 06:2022/BXD).

2. Environmental Impact Assessment (EIA/ĐTM):

-

Design the waste treatment systems (solid, liquid, gas) in accordance with prescribed standards, ensuring the project is environmentally friendly and legally compliant.

STEP 4: DETAILED ENGINEERING DESIGN – IMPLEMENTING SPECIFICS AND MATERIAL QUANTITY TAKE-OFF

After the Conceptual Design is approved, this step converts the drawings into construction-ready details.

1. Detailing the Workshop Structure:

-

Fabrication Drawings (Shop Drawings): Detail every steel component (columns, rafters, purlins) with precise dimensions, weld specifications, and bolted connections.

-

Load Calculations: Re-verify all loads (dead load, live load, wind load, crane load, equipment load) to ensure absolute safety.

2. Detailing the Mechanical and Electrical (M&E) Systems:

-

Piping/Wiring Layout: Detailed routing of the electrical, plumbing, compressed air, and ventilation systems.

-

Bill of Materials (BOM) / Material Quantity Take-Off: Prepare a detailed list specifying the quantity and type of every piece of equipment and material (electrical wires, water pipes, pumps, fans, etc.) to facilitate bidding and procurement.

STEP 5: ISSUING CONSTRUCTION DRAWINGS AND DESIGN VERIFICATION

This is the final step of the workshop design process before handing over the documentation to the construction contractor.

1. Preparing the Workshop Construction Drawing Dossier:

-

Assemble and finalize all detailed Architectural, Structural, and M&E drawings, complete with official seals and necessary signatures.

-

This dossier must be fully comprehensive, clear, and free of contradictions so that the contractor can execute the work accurately on site.

2. Workshop Design Verification (Design Review/Appraisal):

-

This step is mandatory for many industrial projects. The dossier is verified/appraised by an independent consulting unit (or state authority) to check compliance with technical standards (safety, structure) and legal regulations (FPF/PCCC, Environment).

-

The verification process helps detect potential errors, minimize legal risks, and ensure the quality of the work.

STEP 6: FINALIZING THE LEGAL DOSSIER AND HANDOVER

1. Applying for the Workshop Construction Permit:

2. Handover of the Completed Workshop Design Dossier:

-

Formally and completely hand over the approved and verified factory design documentation (including both hard copies and digital files) to the investor to proceed with the bidding and construction phases.

-

Design Warranty: Commit to supporting and resolving any issues arising during the factory construction process.

THE IMPORTANCE OF A STANDARDIZED WORKSHOP DESIGN PROCESS

- Adhering to the 6-step process outlined above helps the workshop project achieve a balance among Functionality (Efficiency), Aesthetics (Branding), and Legality (Safety/Compliance).

- Investing thoroughly in the workshop design phase will save billions of VND in future repair and operating costs.

SVG ENGINEERING - A REPUTABLE FACTORY DESIGN FIRM WITH 20 YEARS OF EXPERIENCE

- Sao Viet Construction Design Consulting and Inspection Joint Stock Company (SVG Engineering) is a prestigious and dedicated firm specializing in Workshop/ Factory Design, Design & Planning, Project Management, and Construction Supervision, backed by 20 years of experience in Vietnam.

- Our headquarters are located in Hai Phong City, with branch offices in Hanoi Capital, Hue City, and Ho Chi Minh City in VietNam.

- With a reputable brand and a team of dedicated, specialized experts, architects, and construction engineers who have extensive experience across numerous real-world factory projects, ranging from small to large scale and spanning various provinces throughout Vietnam, SVG Engineering consistently earns the trust, confidence, and satisfaction of investors/business owners, both domestic and foreign, including those from China, Taiwan, South Korea, and Japan, ...

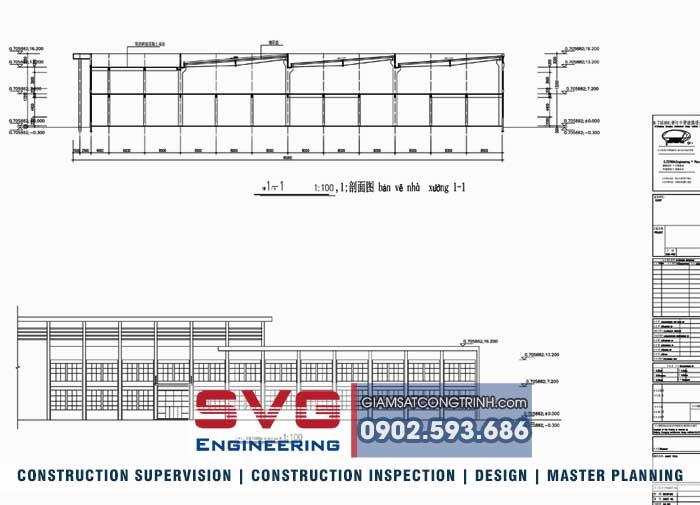

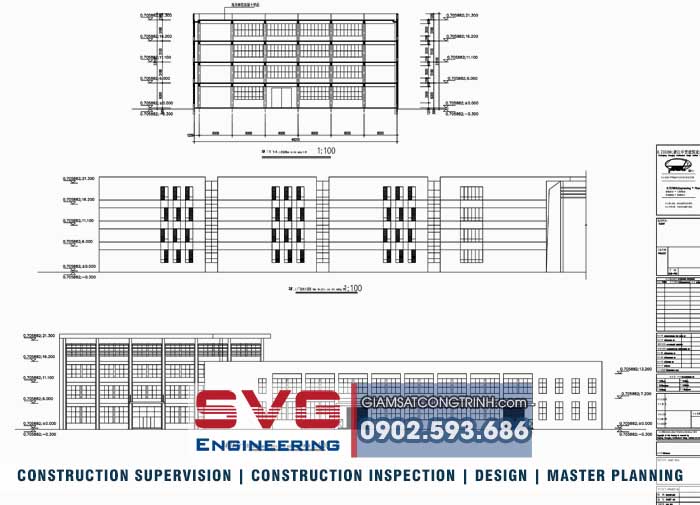

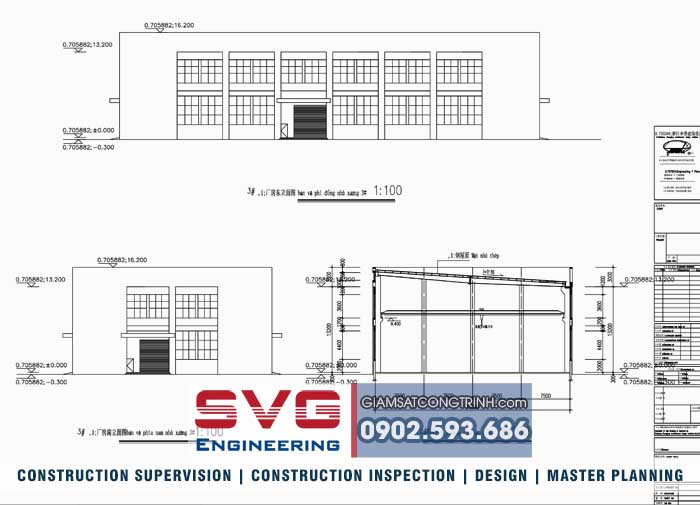

IMAGES OF SVG ENGINEERING PROCESS OF FACTORY DESIGN

COST OF WORKSHOPS DESIGN IN VIETNAM

Please immediately contact Hotline: 0902.593.686 (Mr. Thang) & Email: svg.engineer@gmail.com for support and advice on issues related to Workshop Design in Viet Nam ... Best regards!

VietNam construction consulting - Mr. Thang 0902.593.686

CONTACT US:

SAO VIET CONSTRUCTION DESIGN CONSULTING AND INSPECTION JOINT STOCK COMPANY

🏢 Hai Phong Office :

Address : 7th floor SVG Building - Bui Vien Street - An Bien Ward - Hai Phong City

☎ Tel: (0225) 3.747.819

📞 Hotline: 0902.593.686

📧 Email: svg.engineer@gmail.com

🌎 VietNam Website: giamsatcongtrinh.com

🌎 English Website: en.giamsatcongtrinh.com

🌎 China Website: cn.giamsatcongtrinh.com

Youtube Channel: https://www.youtube.com/@svgengineering

Youtube Channel: https://www.youtube.com/@svgengineering

🏢 Representative offices:

- Ha Noi Branch Office : No. 9/ 81 Hoang Cau Street, Dong Da Ward, Hanoi Capital

- Ho Chi Minh Branch Office: 2/1C Cao Thang Street, Ban Co Ward, Ho Chi Minh City

- Hue Branch Office : M25 Lot , 21 Street, Dong Nam Thuy An, Thanh Thuy Ward, Hue City