Designing and renovating industrial park factories is a way to overcome the deterioration of factory facilities. At the same time, propose design measures to upgrade and strengthen the factory's lifespan. Factory design unit SVG Engineering will help the Investor/Business Owner decide on the best solution to ensure the factory operates safely and in accordance with financial capacity and saves costs.

DESIGN AND RENOVATION OF FACTORY (WORKSHOP) NO. 8 AN DUONG INDUSTRIAL PARK IN HAI PHONG CITY IN VIETNAM

- Construction Project: Design of renovation and reinforcement of the roof floor of factory No. 8

- Address: An Duong Industrial park - An Duong District - Hai Phong City - Viet Nam

- Design Unit: Sao Viet Construction Design Consulting and Inspection Joint Stock Company (SVG Engineering)

- Implementation content: Survey and design to repair cracked roof beams.

- Year of implementation: 2023

CONTENT OF DESIGN AND RENOVATION OF FACTORY (WORKSHOP) NO. 8 AN DUONG INDUSTRIAL PARK IN HAI PHONG CITY IN VIETNAM

1- AREA OF FACTORY ROOF REPAIR 8

- Characteristics of cracked floor locations: The investor and the owner of the factory building have repaired the cracks by injecting glue and waterproofing the roof. The cracks at the time of inspection ranged from 0.15mm to 0.3mm.

- For main beams, secondary beams are also cracked but not in large numbers. The crack width of the beam is about 0.3mm.

2- MEASURES TO REPAIR CRACKED ROOF AT FACTORY 8

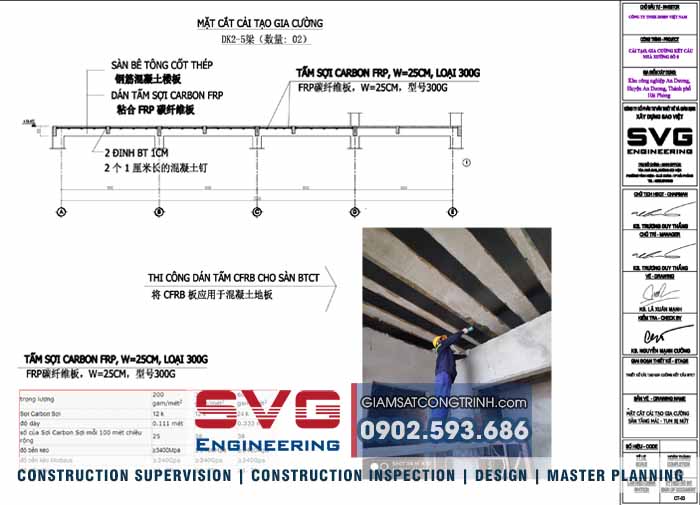

- Based on the characteristics of the crack and the cause of the crack, design consultant SVG Engineering offers a method of strengthening the structure using Fiber Reinforced Polymer (FRP) carbon fiber panels. Below is an image of Carbon FRP panels glued to concrete surfaces including: Beams, Floors, Columns to enhance bearing capacity:

a. Technical specifications of FRB panels

- Length: 100m/roll.

- Width: many sizes 10 cm, 15 cm, 20 cm, 25 cm, 30 cm, 50 cm, 100 cm.

- Thickness: 0.111 mm, 0.167mm, 0.211mm, 0.333mm

This method is currently widely applied. FRP carbon panels are imported by construction units from China, Korea, Japan,...

b. The factory renovation construction process is as follows:

- Step 1: SVG Engineering prepares the surface. Proceed to chisel the factory's mortar layer, then abrade the surface with a specialized grinder, and finally use a dust blower to clean the surface.

- Step 2: We conduct positioning division: Divide and measure the surface to be reinforced into separate spaces, then proceed to roll the primer onto the surface according to the design.

- Step 3: Fill steel gaps and punctured surfaces. Use epoxy to fill gaps to create a flat, balanced surface.

- Step 4: Cut FRP fabric After measuring the design and dividing the distance, proceed to cut the size according to installation requirements.

- Step 5: Prepare to mix glue to cover the fabric. Mix the adhesive and stir well with a specialized mixer. If no coating is used, the adhesive can be applied directly to the surface.

- Step 6: Apply FRP fiber to the surface

Use a support device to paste according to the pre-divided ratio, then press firmly. You can use 1cm concrete nails pinned into the concrete at the beginning and end of the paste to ensure that the paste does not delaminate and drift during the pasting process.

- Step 7: Check the quality Check the distance and gaps between the stickers and between the sticker and the surface. Allow compression load testing before putting into use for projects requiring load testing.

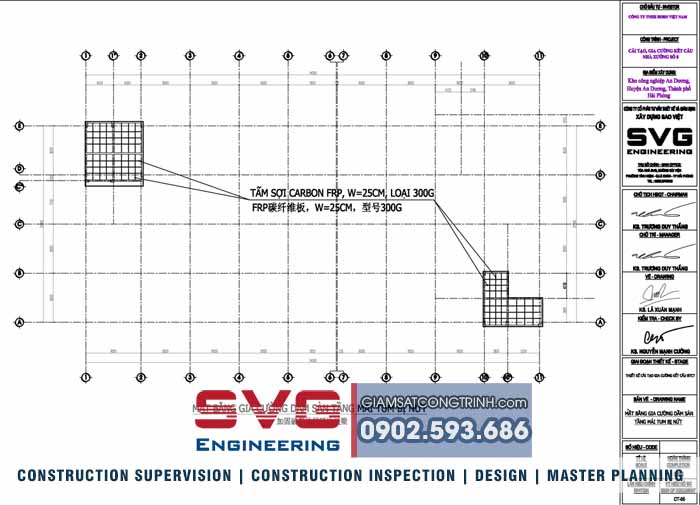

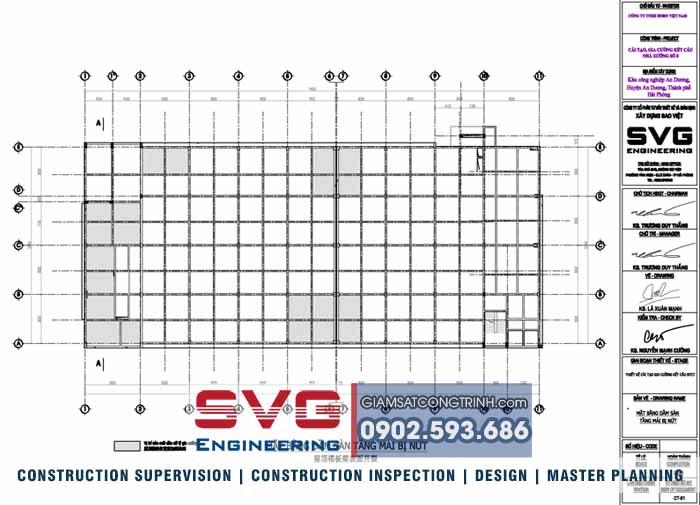

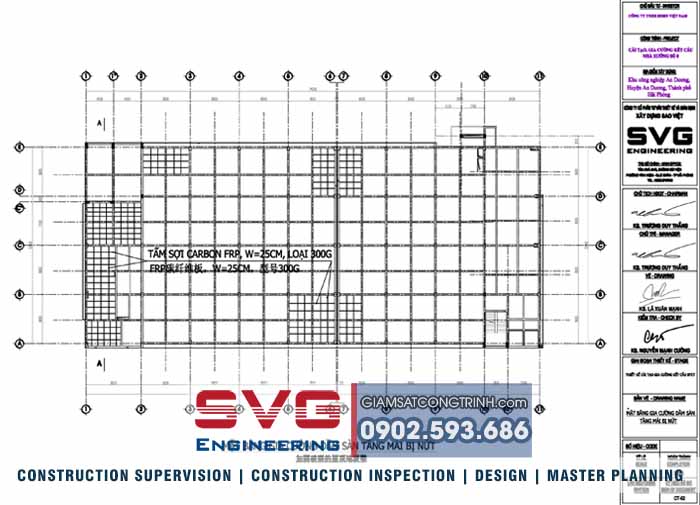

c. Reinforcement design and location of cracked floors in the factory 8

FRP carbon panels are arranged under the concrete floor as follows:

At each floor box, eight Carbon FRP will be equally divided and glued at a distance of 1-1.5m depending on the size of the floor box in both directions.

The FRP Carbon sheet specified for use is a sheet with a width of 25cm, type 300g/m2, thickness of 0.167mm originating from China, Korea, and Japan.

EXPENSE OF DETAILS WORKSHOP DESIGN & FACTORY DESIGN IN VIETNAM

Please immediately contact Hotline: 0902.593.686 (Mr. Thang) & Email: svg.engineer@gmail.com for support and advice on issues related to Workshop design - Factory design in Viet Nam ... Best regards!

VietNam construction consulting - Mr. Thang 0902.593.686

CONTACT US:

SAO VIET CONSTRUCTION DESIGN CONSULTING AND INSPECTION JOINT STOCK COMPANY

🏢 Hai Phong Office :

SVG Building, Bui Vien Street, Le Chan District

☎ Tel: (0225) 3.747.819

📞 Hotline: 0902.593.686

📧 Email: svg.engineer@gmail.com & svg.group2005@gmail.com

🌎 VietNam Website: giamsatcongtrinh.com

🌎 English Website: en.giamsatcongtrinh.com

🌎 China Website: cn.giamsatcongtrinh.com

Youtube Channel: https://www.youtube.com/@svgengineering

Youtube Channel: https://www.youtube.com/@svgengineering

🏢 Representative offices:

1, Ha Noi: No. 9, Alley 81 Hoang Cau Street, Dong Da District

2, Ho Chi Minh: 2/1C Cao Thang Street, 05 Ward, 3 District