To find a reputable factory inspection service, customers can consider a number of factors such as experience participating in inspection of previous factory projects, project quality certification, and scope of inspection services. . Ratings and reviews from previous customers. Sao Viet Construction Design Consulting and Inspection Joint Stock Company (SVG Engineering) is a reputable factory inspection service provider in Vietnam with a brand of nearly 20 years.

REPUTABLE FACTORY INSPECTION SERVICE IN VIETNAM

- Factory inspection is the process of checking and evaluating the structural condition, safety and compliance with factory standards and regulations. SVG Engineering Factory Inspection Service helps detect and promptly fix potential problems related to structure, electrical system, fire protection system and other factors to ensure worker safety. property and assets.

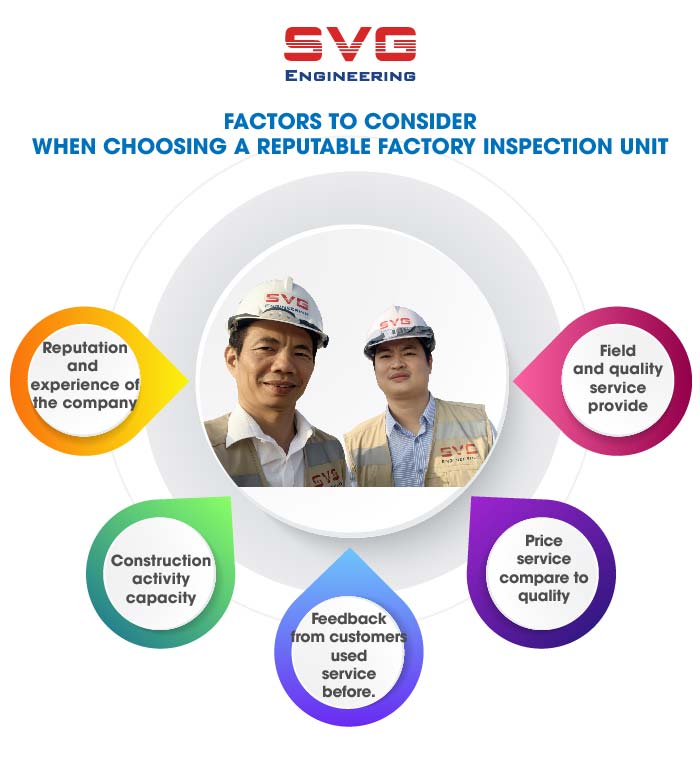

- When choosing a factory inspection unit, customers should consider the following factors:

- Company reputation and experience.

- Capacity for construction activities; Certification and license of the inspection unit.

- Feedback from customers who have used the service before.

- The scope and quality of services the company provides.

- Service price versus quality.

- Sao Viet Construction Design Consulting and Inspection Joint Stock Company (SVG Engineering) is a reputable and dedicated unit in the field of Factory Inspection with nearly 20 years of experience in Vietnam.

HOW LONG IS THE FACTORY INSPECTION CYCLE?

- According to Section 3, Article 17 Construction safety assessment - Circular No. 10/2021/TT-BXD issued on August 25, 2021 as follows:

+ The first project safety assessment is carried out 10 years after the project is put into operation and use according to legal regulations.

+ For the next assessment, the construction safety assessment will be carried out at a frequency of 05 years/week.

- For works that have been put into use, apply according to Article 5.5.3 TCVN 9343:2012 Concrete and reinforced concrete structures - Instructions for maintenance work, Factory inspection cycle is prescribed as follows :

+ Particularly important projects last from 2 to 3 years;

+ The project often has a large number of people working or traveling back and forth for 3 to 5 years;

+ Other industrial and civil works from 5 to 10 years;

+ The structure is resistant to marine climate and chemical corrosion for 1 to 2 years;

PROCESS OF IMPLEMENTING FACTORY INSPECTION IN VIETNAM

Factory inspection is the process of assessing quality and compliance with standards and technical regulations during the construction and operation of the factory. Below is the basic process of SVG Engineering performing factory inspection:

- Before performing factory inspection: Approach the Investor and collect information: (Construction permit drawing; Inspection certificate; Factory structure information; Report request layout inspection report). Then, quote and sign a warehouse inspection contract with the Investor. Reporting costs include (labor costs, machinery costs, sampling costs, repair costs for impact sites to take samples for testing...)

- SVG Engineering plans the factory inspection: Determine the schedule, time and inspection method based on the Investor's requirements and the factory project information provided.

- SVG Engineering's factory inspection team are all qualified construction engineers, have university degrees, and have participated in factory inspection and workshop inspection, inspects warehouse quality and understands the laws while complying with strict provisions of the Law during the inspection process.

- SVG Engineering construction engineers conduct on-site surveys of the factory: Visually observe the factory building with the naked eye to detect cracks and damage to materials or load-bearing structures of the factory. In order for the factory inspection process to be accurate, we often use additional equipment for quality inspection of construction works such as steel rulers, calipers, drills, rebound guns, reinforced steel ultrasonic machines, surveying machine,...

- Prepare an inspection report to certify the load-bearing safety of factory buildings.

- Issuance of factory project quality certificate (if necessary).

SVG ENGINEERING IS A REPUTABLE FACTORY INSPECTION UNIT FOR NEARLY 20 YEARS IN VIETNAM

Sao Viet Construction Design Consulting and Inspection Joint Stock Company (SVG Engineering) is a reputable and dedicated unit in the field of Factory Inspection, Workshop inspection with nearly 20 years of experience in Vietnam.

SVG Engineering is a reputable factory inspection unit for nearly 20 years

EXPENSE OF INDUSTRIAL WORKSHOP (FACTORY) INSPECTION IN VIETNAM

Please immediately contact Hotline: 0902.593.686 (Mr. Thang) & Email: svg.engineer@gmail.com for support and advice on issues related to Workshop (Factory) Inspection in Viet Nam ... Best regards!

VietNam construction consulting - Mr. Thang 0902.593.686

CONTACT US:

SAO VIET CONSTRUCTION DESIGN CONSULTING AND INSPECTION JOINT STOCK COMPANY

🏢 Hai Phong Office :

SVG Building, Bui Vien Street, Le Chan District

☎ Tel: (0225) 3.747.819

📞 Hotline: 0902.593.686

📧 Email: svg.engineer@gmail.com & svg.group2005@gmail.com

🌎 VietNam Website: giamsatcongtrinh.com

🌎 English Website: en.giamsatcongtrinh.com

🌎 China Website: cn.giamsatcongtrinh.com

Youtube Channel: https://www.youtube.com/@svgengineering

Youtube Channel: https://www.youtube.com/@svgengineering

🏢 Representative offices:

1, Ha Noi: No. 9, Alley 81 Hoang Cau Street, Dong Da District

2, Ho Chi Minh: 2/1C Cao Thang Street, 05 Ward, 3 District