House foundation, a core factor that determines the sustainability and safety of every construction, always requires proper attention and investment. In current foundation solutions, Pressing Hydraulic reinforced concrete piles are popular as an optimal choice, especially for constructions with large loads or built on weak soil. To ensure the "eternal" quality of the foundation, the role of construction supervision consulting is indispensable, even the deciding factor for the success or failure of the entire project from the beginning.

HYDRAULIC PILE PRESSING - A SOLID FOUNDATION SOLUTION BUT POTENTIALLY RISKY WITHOUT SUPERVISION

Hydraulic pile pressing - is the process of using hydraulic pressure to lower precast concrete piles or centrifugal piles into the ground, transferring the load of the structure to the harder soil layers below. This method brings many outstanding advantages:

- High load capacity: Reinforced concrete piles have a large load-bearing capacity, suitable for high-rise buildings, apartments, factories, etc.

- Stability: Creates a solid foundation, minimizing subsidence, cracking, and tilting of the structure over time.

- Fast construction time: Pile driving is often faster, especially when using modern machinery.

- Less impact on neighboring structures: Vibrations and noise during the pile pressing process are significantly reduced compared to the pile driving method.

However, besides the advantages, the process of pressing reinforced concrete piles also has many serious risks if not strictly controlled:

- Pile quality does not meet requirements: Piles manufactured with incorrect specifications, wrong concrete grade, insufficient steel... will directly affect the load-bearing capacity.

- Incorrect construction techniques: Piles driven in the wrong position, not in the right axis, wrong direction, insufficient driving force, or driving through good soil layers... can cause local subsidence, wall cracks, and even collapse of the structure later.

- Complex geological conditions: Sudden changes in geology that are not detected and handled promptly can lead to piles not reaching the design depth or being destroyed during the driving process.

- Environmental and labor safety issues: Dust, noise, safety for workers and neighboring structures are also challenges that need to be monitored.

This is when the role of the supervision consultant becomes extremely important to ensure the overall quality of the construction foundation.

THE CORE ROLE OF SUPERVISION CONSULTANTS IN HYDRAULIC PILE PRESSING

The construction supervision consultant is not only an inspector but also a strategic partner, protecting the interests of the Investor and ensuring the highest quality of the project. With Reinforced Concrete Pile Driving, this role is clearly demonstrated through the following aspects:

1. Control of design documents and construction preparation:

Before the machines started working, construction supervision had to be involved:

-

Check the completeness and validity of design documents: Ensure that pile design drawings, geological survey documents, pile load-bearing capacity calculations, and technical instructions are accurate and in accordance with current standards.

-

Check pile quality before pressing: Supervisors must check the origin, quality certificate of the pile manufacturer (steel, concrete), geometric dimensions, straightness of the pile, location of joints, and whether the pile is cracked or broken. Any error at this stage can lead to pile damage during pressing.

-

Check the construction site: Make sure the site is wide enough, leveled to the correct height, has a path for machinery, and is free of underground structures (electricity, water, fiber optic cables) if any.

2. Supervise the entire pile pressing process:

This is the most important stage, where the construction supervisor must be constantly present on site:

-

Check pile pressing equipment: Make sure the driving machine has full inspection documents, stable operation, pressure gauge is accurately calibrated. Pile pressing force must be recorded and compared with the design.

-

Pile positioning and elevation: The supervising engineer must check the pile center, locate the pile pressing position according to the design drawing, ensure the verticality of the pile during pressing and the elevation of the pile tip compared to the reference mark. Even a small deviation in position can affect the structure above.

-

Supervising pressure and speed: This is a key factor. The supervising engineer needs to record the pile section pressure chart (pressure according to depth). The pressure must increase gradually and reach the final pressure (Pmax) according to the design requirements. If the pile reaches Pmax earlier than the design, or does not reach Pmax even though it has reached the design depth, the supervisor must give a warning and propose a timely solution (for example: additional test pressure, pilot drilling, waiting for settlement...).

-

Pile joint supervision: Check the quality of the joints (welding, concrete) to meet the standards, ensuring a solid connection between pile sections. Faults in the joints can cause the pile to break horizontally when bearing the load.

-

Handling arising problems: During the pressing process, problems may occur such as skewed piles, broken piles, piles not reaching the design depth... Construction supervisors must have the knowledge and experience to analyze the causes, propose appropriate and quick solutions, and avoid affecting progress and quality.

3. Completing Documents and Quality Assessment after Construction:

After pile pressing is completed, supervising continues with:

- Making acceptance report: Record full information about the number of piles, location, pressing depth, pressing pressure of each pile, incidents and handling methods. This is an important legal basis for the entire project.

- Overall assessment of foundation quality: Based on the collected data, the construction supervision engineer will give an overview of the foundation quality, ensuring that the technical indicators meet the design requirements and are safe for the project.

SVG ENGINEERING IS A PRESTIGIOUS CONSTRUCTION SUPERVISION CONSULTANT FOR 20 YEARS IN VIETNAM

SVG Engineering is an experienced supervision consultant in Vietnam. We have our Head Office in Hai Phong City and 03 representative offices in Hanoi, Hue City and Ho Chi Minh City. We are committed to providing professional and strict concrete pile pressing supervision services, from preparation to completion, helping investors:

- Ensure optimal foundation quality: Avoid risks of subsidence, cracking, and tilting, providing absolute peace of mind for the project.

- Save costs and time: Detect and handle errors early, avoiding costly repairs later. Ensure construction progress according to plan.

- Transparency during construction: Provide detailed, objective reports on quality and progress.

- Fully comply with regulations and standards: Help the project meet standards, making the acceptance process easier.

Investing in a reputable consulting and supervision unit is not an expense but a smart investment, ensuring the sustainable value and safety of your project for decades to come. Don't let the potential risks of unsupervised pile pressing affect your property and safety!

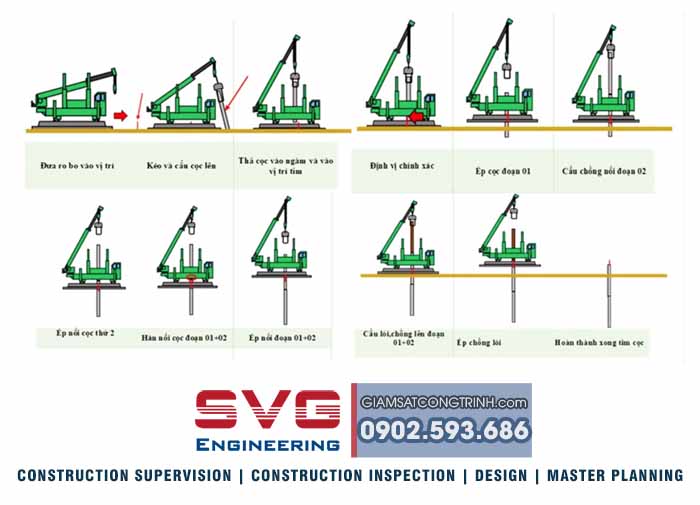

IMAGES OF SVG ENGINEERS SUPERVISE PROCESS PILE PRESSING

COST OF HIRING CONSTRUCTION SUPERVISION CONSULTING IN VIETNAM

Please immediately contact Hotline: 0902.593.686 (Mr. Thang) & Email: svg.engineer@gmail.com for support and advice on issues related to Construction supervision Consulting in Viet Nam ... Best regards!

VietNam construction consulting - Mr. Thang 0902.593.686

CONTACT US:

SAO VIET CONSTRUCTION DESIGN CONSULTING AND INSPECTION JOINT STOCK COMPANY

🏢 Hai Phong Office :

Address : 7th floor SVG Building - Bui Vien Street - An Bien Ward - Hai Phong City

☎ Tel: (0225) 3.747.819

📞 Hotline: 0902.593.686

📧 Email: svg.engineer@gmail.com

🌎 VietNam Website: giamsatcongtrinh.com

🌎 English Website: en.giamsatcongtrinh.com

🌎 China Website: cn.giamsatcongtrinh.com

Youtube Channel: https://www.youtube.com/@svgengineering

Youtube Channel: https://www.youtube.com/@svgengineering

🏢 Representative offices:

- Ha Noi Branch Office : No. 9/ 81 Hoang Cau Street, Dong Da Ward, Hanoi Capital

- Ho Chi Minh Branch Office: 2/1C Cao Thang Street, Ban Co Ward, Ho Chi Minh City

- Hue Branch Office : M25 Lot , 21 Street, Dong Nam Thuy An, Thanh Thuy Ward, Hue City