Workshop construction inspection is an activity to check,evaluate the bearing capacity and stability of the structure of the workshop. Construction Inspection to detect abnormal manifestations and provide timely remedial measures to maintain the bearing capacity of the workshop, ensure the life of the workshop, ensure the safety of people and property as well as such as helping to maintain production activities inside the workshop.

WORKSHOP CONSTRUCTION INSPECTION OF LIANYUE COMPANY (VIETNAM) - AN DUONG INDUSTRIAL PARK - HAI PHONG CITY

Project: Construction Inspection of cracked concrete roof of Workshop of LianYue Company

Unit soliciting for inspection: Branch of Kien An Joint Stock Company (Group) in Shenzhen City in Vietnam

Location: An Duong Industrial Park, An Duong District, Hai Phong City

Inspection Unit: Sao Viet Design Consulting and Construction Supervisory Joint stock Company

Year of implementation: 2022

.jpg)

Workshop construction inspection of LianYue Company (Vietnam)

Reinforced concrete roof floor of workshop of LianYue (Vietnam) Co., Ltd., after concreting, there is a phenomenon of concrete floor cracking when not treated with waterproofing, causing leakage and water infiltration. The phenomenon of concrete floor cracking is very common, this situation has significantly affected the quality of the construction.There are many reasons for this, both objective and subjective. So what is the main cause of the concrete floor cracking phenomenon in LianYue workshop? How to handle? Let's find out with SVG Engineering and come up with a solution to this problem.

CONTENTS FOR WORKSHOP CONSTRUCTION INSPECTION

- Before carrying out quality workshop construction inspection: Approach the Investor and collect information: (Building permit drawing, Inspection certificate permit, Layout requesting inspection report). After that, Quote and sign a contract workshop construction inspection with the Investor. Report costs include ( labor costs, machine costs, sample costs, repair costs...)

A - INSPECTION THE CURRENT CONDITION OF THE WORKSHOP:

- The inspection location is the concrete floor of the main workshop:

The inspection location is the concrete floor of the main workshop

The inspection location is the concrete floor of the main workshop

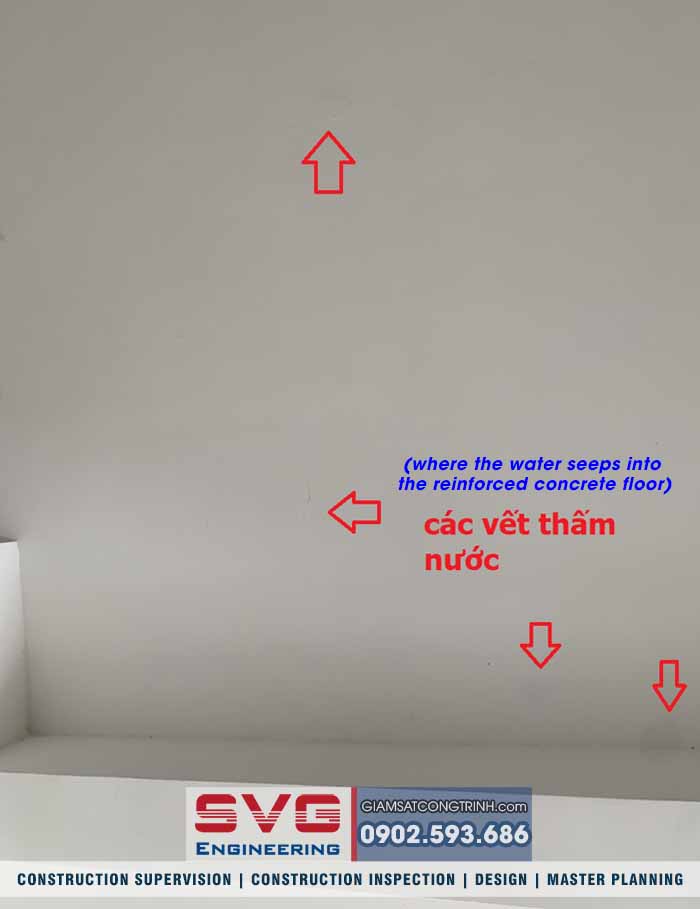

Where the water seeps into the reinforced concrete floor

- There are cracks observed from below at ¼ structural span and ½ structural span.

- The cracks run in unknown directions.

- Most of the cracks are leaking and seeping in water.

B - WORKSHOP CONSTRUCTION INSPECTION AT THE SITE:

- At the time of survey and assessment, the concrete floor is being glued with bitumen oil paper for waterproofing.

- Determine 2 drilling locations with cracks, which are the M1, M2 holes located at 1/5-1/4 of the structural span.

- Determine 1 drilling location without cracks, which is the M3 hole located at 1/2 of the structural span.

SVG Engineering conducts drilling for floor concrete samples

Determine 3 drilling locations which are the M1, M2, M3 holes

- Pictures of actual drilling samples:

Measure the length of the drill sample M1

Measure the concrete protection class of the drill sample M1

Measure the length of the drill sample M2

Measure the concrete protection class of the drill sample M2

Measure the length of the drill sample M3

Measure the concrete protection class of the drill sample M3

- Determination of specifications of drilling samples length and concrete protection layer thickness after drilling concrete samples

C- MAKING STATISTIC TABLE OF DATA OF WORKSHOP QUALITY INSPECTION

- Make a summary table of the length and thickness of the protective layer: Determine the specifications of the width and length of the cracks in the concrete samples.

- Make a summary table of width and length parameters of cracks.

Notes :

- Cracks have the characteristic of growing from the top to the bottom

- Sample M1 has 1 crack, Sample M2 has 2 cracks, Sample M3 has no cracks

Measurement of crack parameters of drilling sample M1

Measurement of crack parameters of drilling sample M1

Measurement of crack parameters of drilling sample M1

Measurement of crack parameters of drilling sample M2

Measurement of crack parameters of drilling sample M2

D- WORKSHOP CONSTRUCTION INSPECTION IN LABORATORY:

In 3 samples M1, M2, M3, sample M3 is eligible to test concrete strength, so we put M3 sample to be destroyed to determine concrete strength. The results are shown: Concrete strength of sample M3 is converted to 450kg/cm2.

Drilling sample M3 - Inspection concrete strength

Drilling sample M3 - Inspection concrete strength

Drilling sample M3 - Take the steel in the concrete sample

Drilling sample M3 - Take the steel in the concrete sample

E - ASSESSMENT AND CONCLUSION OF WORKSHOP CONSTRUCTION INSPECTION:

According to the requirements of the contract, the inspection unit does not check the design documents, design calculations and quality management records, so we would like to make an assessment and conclusion on the data performed:

1. High probability cracking is not due to design.

2. High probability of cracking is not due to concrete strength.

3. High probability of cracking is due to one or more of the following causes:

3.1- Because the concrete used for construction is M350, which is high strength concrete, it is possible that the manufacturer has used high strength cement or additives with fast setting time or hardening additives to make the water loss process happens faster than usual. Trong khi:

3.2- The maintenance process of concrete does not guarantee enough water and the maintenance time is not guaranteed, so the concrete loses water quickly, causing the concrete shrinkage to crack the floor as current status. According to TCVN 8828:2011, the curing time for heavy concrete is 3-4 days and nights. This is also quite consistent with the shape of the crack on the drilled samples, that is: the crack widens at the top and the crack direction develops from top to bottom due to the faster surface temperature and water loss rate.

3.3- Weather conditions when pouring concrete is too hot, causing rapid water loss or because the formwork is not guaranteed to lose part of the water in the concrete.

F - METHOD TO TREAT CRACKS OF CONCRETE FLOORS OF WORKSHOP:

Treating cracked concrete floors is very important to secure the entire structural system. Processing needs to be carried out meticulously and in detail. Based on the assessment and conclusion inspection of the factory structure in the summary report, SVG Engineering will take appropriate treatment methods.

-

Carry out special glue injection seal gaps, fill and treat cracks. The purpose is to prevent air and water from entering and affecting the steel structure in the concrete. It is possible to use waterproofing materials such as Sika, Intoc to treat cracks.

-

Clean the floor surface after the reinforcement and treatment is complete.

CAPACITY CONDITIONS OF SVG COMPANY AND TEAM OF CONSTRUCTION ENGINEERS PARTICIPATE IN FACTORY INSPECTION

Over 17 years of building a prestigious brand, SVG Engineering has successfully implemented many bidding packages in the field of construction inspection, including workshop construction inspection and factory construction inspection in Hai Phong industrial zone as well as other provinces into the country. SVG Engineering's team of engineers are professionally trained with practice certificates suitable to the level and type of construction inspection works are participated.

SVG Engineering is a reputable workshop construction inspection company

Some workshop/factory projects that SVG Engineering inspect throughout the provinces:

- Construction inspection of warehouses of Sunrise Factory Project (Vietnam)

- Residental construction inspection

COST ESTIMATE OF WORKSHOP CONSTRUCTION INSPECTION

Please immediately contact HOTLINE 0902.593.686 (Mr. Thang) for support and advice on issues related to workshop construction inspection, factory construction inspection. Best regards!

CONTACT INFORMATION:

SAO VIET DESIGN CONSULTING AND CONSTRUCTION SUPERVISORY JOINT STOCK COMPANY

Hai Phong Office:

SVG Building - Bui Vien Street - Le Chan District - Hai Phong City

Tel: (0225) 3.747.819

Website: giamsatcongtrinh.com & en.giamsatcongtrinh.com

Hotline: 0902.593.686 - 0936.547.819

Email: svg.group2005@gmail.com & svg.engineer@gmail.com

Branch office:

1, Ha Noi Branch Office: No. 9, Alley 81 Hoang Cau Street, Dong Da District, Hanoi Capital

2, Ho Chi Minh Branch Office: 2/1C Cao Thang Street, 05 Ward, 3 District, Ho Chi Minh City