SVG Engineering is an inspection and certification unit for structural safety and factory (workshop) load-bearing safety - Factory (workshop) safety quality certification inspection includes: Inspection of dyeing factories, garment factories, leather shoe factories, factories for import-export production, etc. Periodically inspect factories to determine the quality of the current state of factory structures, calculate and test the bearing capacity, evaluate the safety of the factory (workshop), Issue a certificate to the factory to ensure sufficient safety and load-bearing capacity to serve production needs for a certain period of time (3-5 years).

HOW PERIODICALLY SHOULD A FACTORY INSPECTION BE PERIOD

Periodic inspection of factory buildings aims to promptly detect signs of damage, subsidence, cracking of factory structures during use for production. From there, the factory inspection unit provides early solutions and solutions to maintain load-bearing safety and prolong the life of the factory building.

Periodic inspection cycle of construction items according to section 5.5.3 of national standard TCVN 9343:2012 “Concrete and reinforced concrete structures – Instructions for maintenance work” is as follows:

– Particularly important construction projects last 2 to 3 years.

– The construction project often has a large number of people working or passing by for 3 to 5 years.

– Other industrial and civil construction projects from 5 to 10 years.

– The construction project is regularly subjected to marine climate corrosion and chemical corrosion for 1 to 2 years.

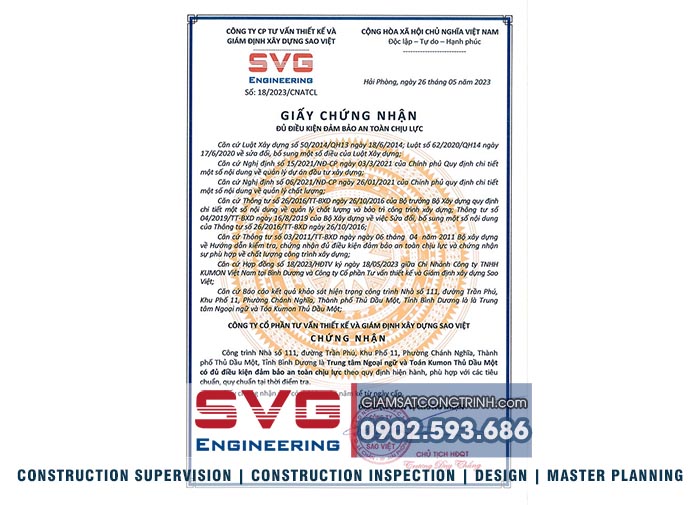

After inspecting the factory, if the factory's structure ensures safety in terms of bearing capacity and safety during use during the production process, SVG Engineering will issue a Construction Quality Certificate to the factory (workshop).

Below is a sample of Factory (Workshop) Quality Certificate inspected by SVG Engineering:

CAPACITY OF THE ORGANIZATION OR UNIT INSPECTION OF FACTORY (WORKSHOP) CONSTRUCTION

- Construction inspection organization SVG Engineering has a Certificate of Construction Activities Capacity issued by the Hai Phong Department of Construction.

- Sao Viet Construction Design Consulting and Inspection Joint Stock Company (SVG Engineering) has enough capacity to carry out construction inspection activities (Certificate of capacity for construction activities, practicing certificate of the chairperson) for civil and industrial works, transportation (waterways), technical infrastructure.

SOME IMAGES OF SVG ENGINEERING'S FACTORY (WORKSHOP) INSPECTION

1- INSPECTION OF TEXTILE AND DYEING FACTORY (WORKSHOP) IN PHO NOI B INDUSTRIAL PARK IN HUNG YEN PROVINCE

2- INSPECTION OF THE DONGDO ELECTRONICS FACTORY (WORKSHOP) IN HAI PHONG

3- INSPECTION OF CUU LONG STEEL FACTORY (WORKSHOP)

4- LIANYUE FACTORY (WORKSHOP) INSPECTION IN VIETNAM

5- LIANYUE FACTORY (WORKSHOP) INSPECTION IN NAM DINH PROVINCE IN VIETNAM

6- SUNVIGOR FACTORY (WORKSHOP) INSPECTION IN VIETNAM

7- VALLEYLOGISTIC FACTORY (WORKSHOP) INSPECTION IN YEN PHONG INDUSTRIAL PARK IN BAC NINH PROVINCE IN VIETNAM

8- DONGKANG FACTORY (WORKSHOP) INSPECTION IN DEEP C2B INDUSTRIAL PARK IN HAI PHONG CITY IN VIETNAM

9- CHIFONT FACTORY (WORKSHOP) INSPECTION IN VIETNAM

10- DST VINA 2 FACTORY (WORKSHOP) INSPECTION IN VINH PHUC PROVINCE IN VIETNAM

FACTORY (WORKSHOP) INSPECTION IN VIETNAM – SVG ENGINEERING

1. Survey the current status of the project, visually observe the factory (workshop) : At the scene, we visually observe, inspect and use construction inspection equipment.

2. Check the geometric dimensions of factory (workshop) structures: Inspect the site, measure and re-determine the size of load-bearing structures such as beams, floors, and columns of factory (workshop) buildings, and re-measure and draw according to reality.

3. Check factory (workshop) bolt connections: Check the number of connecting bolts, bolt diameter and critical tightening level of connecting bolts M10-M60. Use a common steel ruler to directly measure the structure, an electronic caliper, and tighten a torque wrench with a 2m arm length.

4. Check the strength of factory (workshop) concrete: Check concrete strength by using rebound gun test combined with Construction Standards table (TCVN)

5. Check the quantity, diameter of rebar and thickness of concrete layer protecting factory rebar: Using steel reinforcement ultrasonic equipment combined with chisel drilling, measuring with steel rulers and electronic calipers.

6. Check beam deflection, floor box deflection, and factory roof deflection

7. Check column verticality and column tilt: Performed by surveying method measuring column tilt, using Leica electronic total station, measuring and determining coordinates of points, calculating and determining column verticality.

8. Prepare a (workshop) factory quality inspection report to certify the factory - (Workshop) Factory inspection

EXPENSE OF FACTORY (WORKSHOP) CONSTRUCTION INSPECTION IN VIETNAM

Please immediately contact Hotline: 0902.593.686 (Mr. Thang) & Email: svg.engineer@gmail.com for support and advice on issues related to Factory (workshop) Construction inspection in Viet Nam ... Best regards!

VietNam construction consulting - Mr. Thang 0902.593.686

CONTACT US:

SAO VIET CONSTRUCTION DESIGN CONSULTING AND INSPECTION JOINT STOCK COMPANY

🏢 Hai Phong Office :

SVG Building, Bui Vien Street, Le Chan District

☎ Tel: (0225) 3.747.819

📞 Hotline: 0902.593.686

📧 Email: svg.engineer@gmail.com & svg.group2005@gmail.com

🌎 VietNam Website: giamsatcongtrinh.com

🌎 English Website: en.giamsatcongtrinh.com

🌎 China Website: cn.giamsatcongtrinh.com

Youtube Channel: https://www.youtube.com/@svgengineering

Youtube Channel: https://www.youtube.com/@svgengineering

🏢 Representative offices:

1, Ha Noi: No. 9, Alley 81 Hoang Cau Street, Dong Da District

2, Ho Chi Minh: 2/1C Cao Thang Street, 05 Ward, 3 Distric